Quality Assurance

Shree Luxmi Fasteners are guided by a set of stringent quality control policy adopted by the management. According to this, we seek to maintain qualitative production system at every stage of the manufacturing. After sales service is the integral part of our quality control policy. Besides, our products are tested on the parameters like Abrasion resistance, Length and diameter, Corrosion resistance, Tensile strength, Metric bolt strength and Thread dimensions.

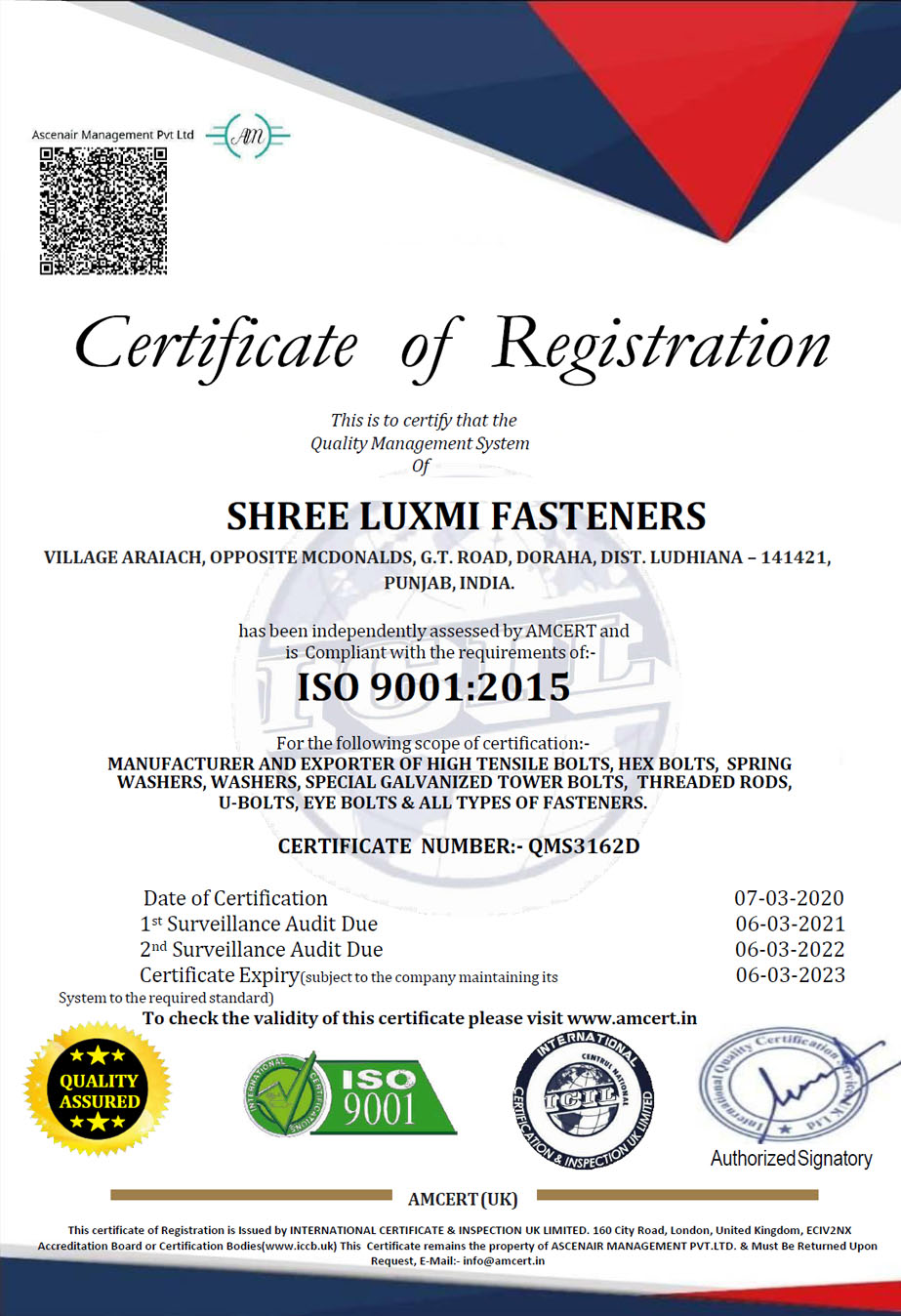

ISO Certification

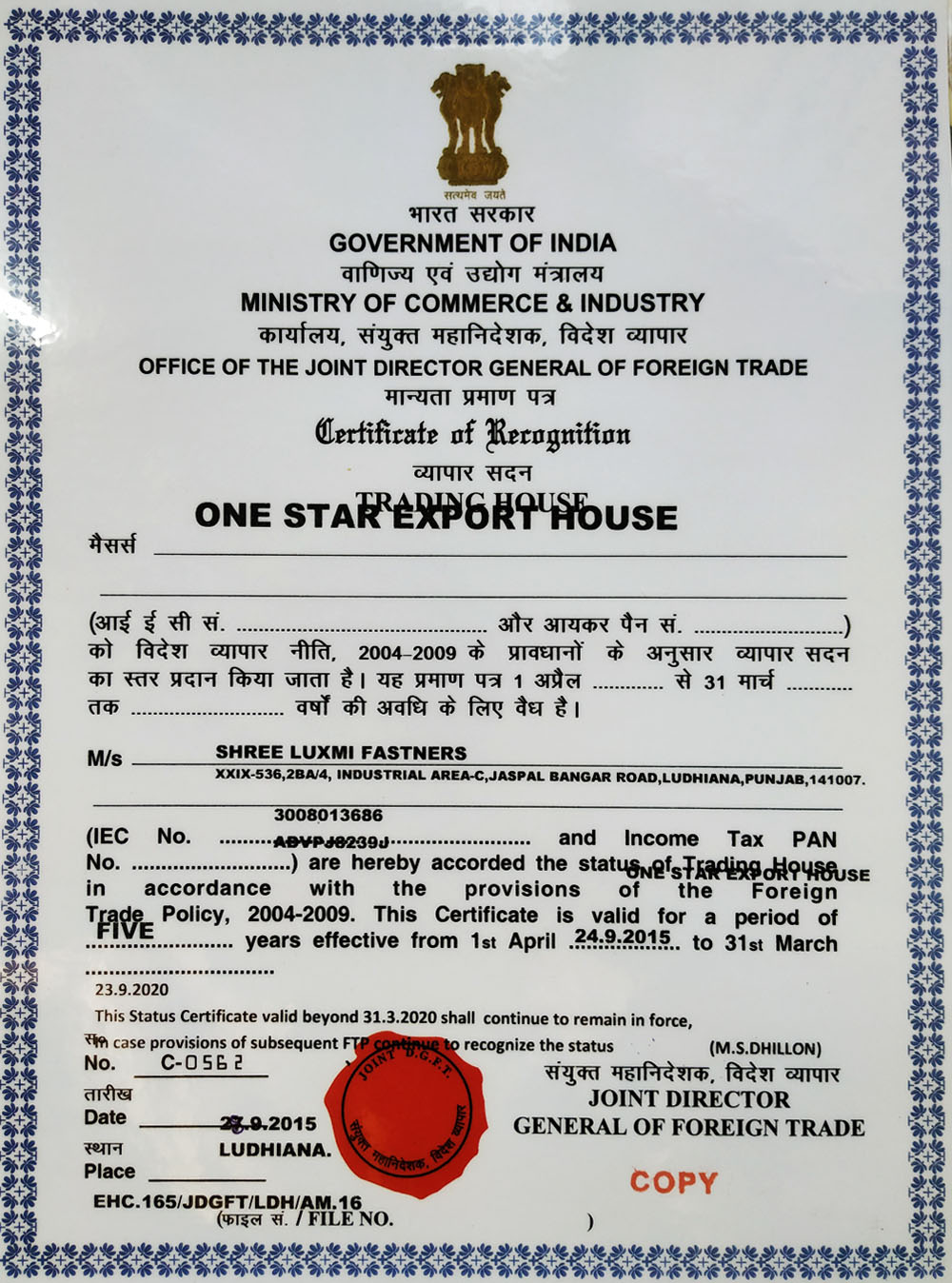

Being an ISO 9001:2015 certified company and the leading company awarded by the government of India with the honor of "One Star Export House," SLF has achieved the sales of up to US$8 million in export. Facing the fierce competition from India and other countries, SLF's main goal is to satisfy customers' demand to its fullest and achieve on time delivery at all times. On the other hand, in order to locate more business opportunities in the U.S.A market, SLF had also exhibited at the National Industrial Fastener & Mill Supply Expo in October 2016. We know and understand the needs of US clients and our step-by-step quality procedures & control of product manufacturing at every stage help us retain the confidence in our clients worldwide.

Quality Testing

Shree Luxmi Fasteners maintain a high level of quality standards through stringent quality test at all levels of production from our committed personnel along with sound infrastructure. We use fine quality of raw materials for our products to ensure that we get the best quality of finished products. We also provide material test certificates for our products during supplying of products or as demanded by client. We have a strict quality test to ensure the dimensions and mechanical properties of the materials matches the client’s requirements.

For us, quality is about utility and applicability for which the product was bought rather than only durability and defect free nature of the product. Therefore, we try to produce products that can fulfil different purpose and requirements. We have a stringent quality test to ensure that the product has zero defects and are of good quality with international standards. Each stage of production has its own quality test and we only source raw materials from reputed, reliable and established vendors.

Quality Control

We have the most advanced technologies and qualified and efficient personnel for inspection, we are also associated with Government Approved laboratories to ensure that the materials supplied by us are as per required specification. With multiple quality checks placed at every step of the manufacturing process, we ensure that only the high quality fasteners of international standards reaches our dedicated packaging unit. Here, it is handled and packed with care, so that it is ready to be delivered anywhere around the world in the same pristine condition that it has been manufactured. Our basic objective is to cater to the various needs of our clients and provide them with high-quality products for their project needs. Our quality assurance system assures each product to pass through following processes and quality systems:

- Material Control System

- Process Control System

- Machining and Dimensional Control

- Certification and Supplementary Test

- Finishing and Marketing